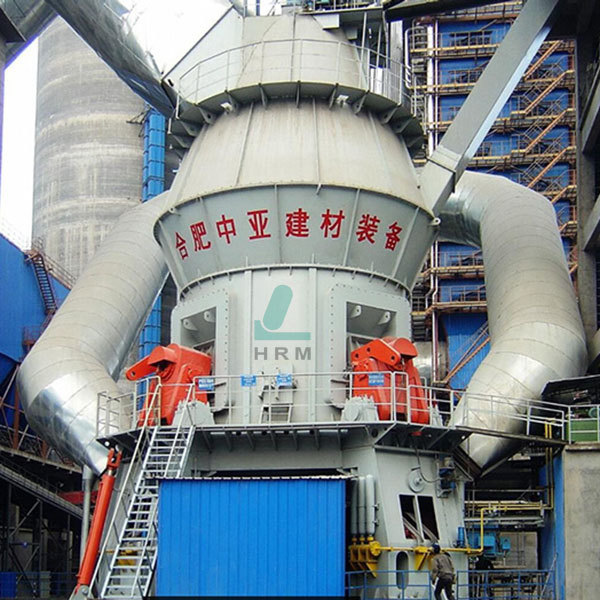

HRM Raw Mill

REXFOS Pumps is an international pump company which is manufacture in China. REXFOS is technology driven and market-oriented. We offer products for water treatment, pulp & paper, power, chemical, oil & gas and general industries. Since 1986.

Category:

Product Description

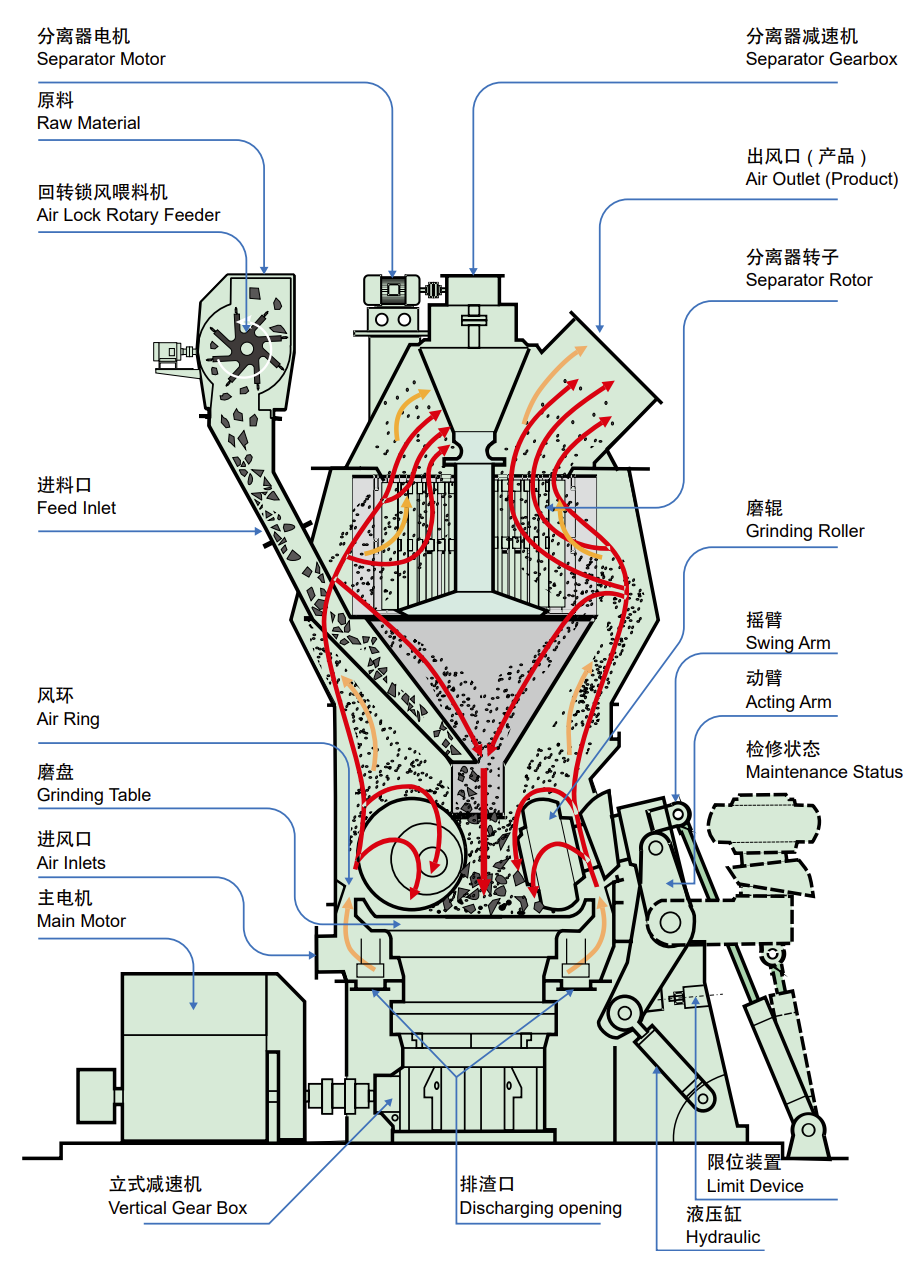

HRM Raw vertical roller mill are new equipment designed since 1984, It through grinding rollers to roll & press the materials(0-40mm)on the rotating grinding pan with pressure and grind them to be reached up to the relevant fineness. It has good advantages of high grinding efficiency, big drying capacity, product fineness is easy to be adjusted, low noise, low powder consumption, simple process flow, low abrasiveness, operating cost saving and ect.

Technical Parameters

|

Model |

HRM30/2 |

HRM34/3 |

HRM42/4 |

HRM44/4 |

HRM50/4 |

HRM53/4 |

HRM56/4 |

HRM60/4 |

HRM65/6 |

|

Grinding disc diameter(mm) |

2500 |

2800 |

3400 |

3700 |

4200 |

4500 |

4800 |

5100 |

5600 |

|

Yield(t/h) |

85~100 |

130~160 |

190~240 |

240~300 |

320~400 |

400~500 |

440~550 |

550~670 |

600~730 |

|

Raw material moisture(%) |

<8~10 |

||||||||

|

Raw meal fineness |

R0.08<14%(80Micron sieve) |

||||||||

|

Raw material moisture(%) |

≤1 |

||||||||

|

Main motor power(kW) |

800/900 |

1120/1250 |

1800/2000 |

2500/2800 |

3150/3350 |

3800/4200 |

4200/4500 |

5000/5400 |

5600/6000 |

HRM Vertical Raw Mill,

Why choose HRM?

High Performance Characteristics by with 40 years experience:

- High efficient grinding. Utilizing advanced material layer grinding principle saves 20-30% power compared to that of ball mill, meanwhile the energy-saving effect will be more obvious by the increasing of water content in raw material.

- Better drying capacity. It could take use wasted hot gas of kiln to dry the material, while it could dry and grind the raw material for the kiln with over 15% water content.

- HRM vertical mill takes up smaller area and its processing flow is simple. It is the equipment with the function of fine crushing, drying, grinding, separating and conveying, there is no need for equipping with drying, separating and lifting equipments. And its workshop area is only 70% of that for ball mill system, while its space is only 50-60% of that for ball mill system.

- Low noise, little dust emission, clean operation environment. Grinding roller and abrasive disk will not directly contact during operation that is to say there is no metal impacting, thus the noise is 20-25db less than that of ball mill system. The whole system utilizes complete sealed negative pressure operation, there is no dust emission, so the production environment is clean.

- Low abrasion, little metallic pollution for the products. Normally the metal abrasion is only 5~10g per ton production, thus the metallic pollution for the product is little.

- Roll sleeve of grinding roller could be turn over for using which could extend the useful life and cut down the production cost. And it’s operation and maintenance is convenient;

- The chemical content of grinding products is stable and the gradation of grain is even, this is propitious to calacine.

- more than 3000 clients chioce.

Model HRM Vertical Mill - Buy Vertical Raw Mill ,

HRM Vertical Mill, Find Complete Details about Vertical Raw Mill from Other Construction Machinery Supplier or Manufacturer

HRM1900,HRM2400,HRM2800,HRM,3400,HRM3700,HRM2200,HRM1250,HRM1100,HRM24-28,HRM3400E,HRM1700M,HRM1300M,HRM1500M,HRM1700X,HRM3700E,HRM4200,HRM29.3M,HRM22/3,HRM34.3M,HRM27-29,HRM34.3.

HRX10.2X, HRX14.2X, HRX16.2X, HRX17.2X, HRX18.2X, HRX20.2X, HRX22.2X, HRX22.3X,

HRX25.2X, HRX27.2X, HRX27.3X, HRX29.3X, HRX32.3X, HRX34.3X, HRX43.4X, HRX46.4X,

HRX51.4X,HRX58.4X, HRM10.2M, HRM14.2M, HRM16.2M, HRM17.2M, HRM18.2M,

HRM20.2M, HRM22.2M, HRM25.2M, HRM27.2M, HRM27.3M,HRM29.3M,

HRM32.3M, HRM34.3M, HRM43.4M, HRM46.4M, HRM51.4M, HRM58.4M, HRM20.2Y,

HRM25.2Y, HRM31.2Y, HRM36.3Y, HRM43.4Y, HRM46.4Y,HRM54.4Y, HRM58.4Y, HRM35.3X

HRM800M, HRM1100M, HRM1250M, HRM1300M,HRM1500M,HRM1700M, HRM1900M, HRM2200M, HRM2400M, HRM2800M, HRM3400, HRM3700, HRM4200, HRM4800, HRM3400E

HRM800, HRM1100, HRM1250, HRM1300,HRM1500,HRM1700, HRM1900, HRM2200, HRM2400, HRM2800,

HRM1300X,HRM1500X, HRM1700X, HRM1900X, HRM2200X, HRM2400X, HRM2800K, HRM3700K

Key words:

Vertical Mill / Related Equipment / Fast Moving Parts / API Vertical Pumps General Industrial Pumps

LATEST NEWS

Thank You for Your Attention to ZhongYa!

Send us your needs for your business, we have professional service team to answer you !